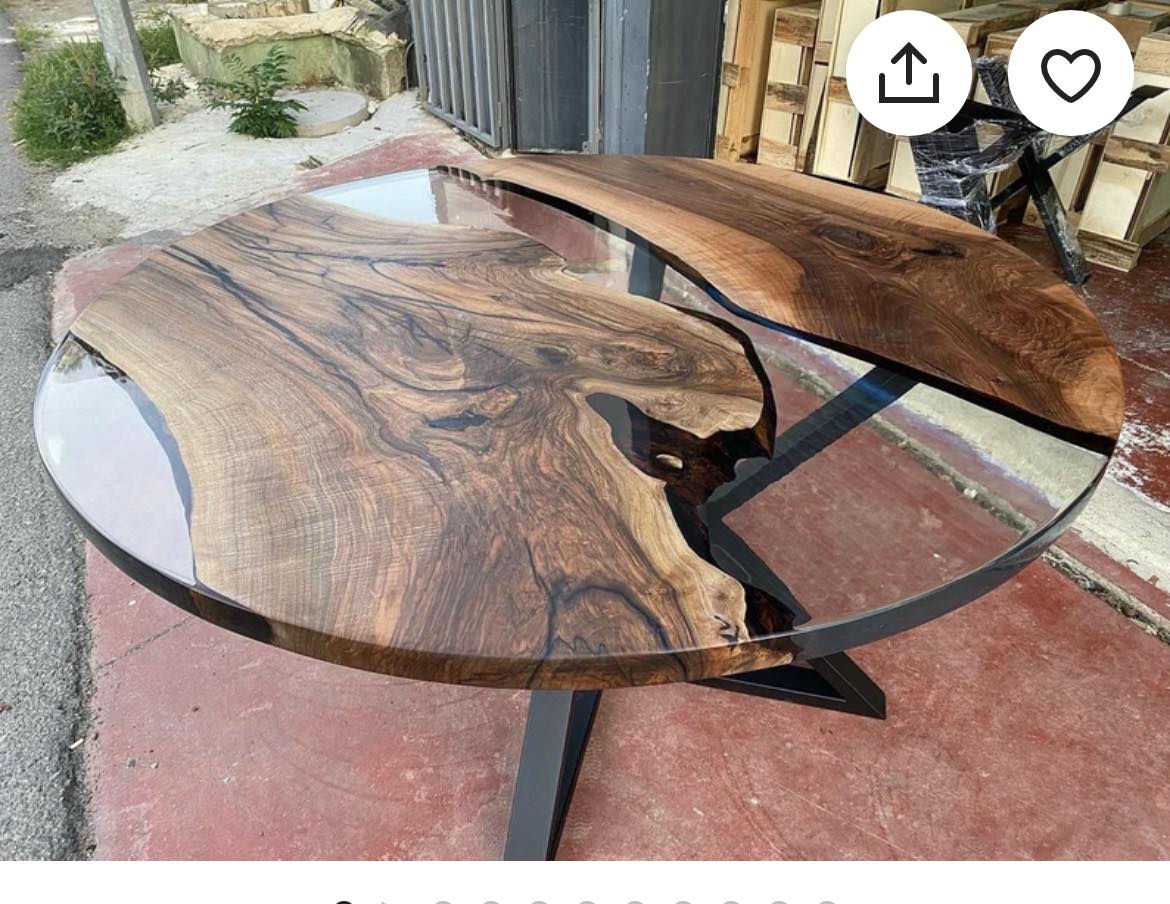

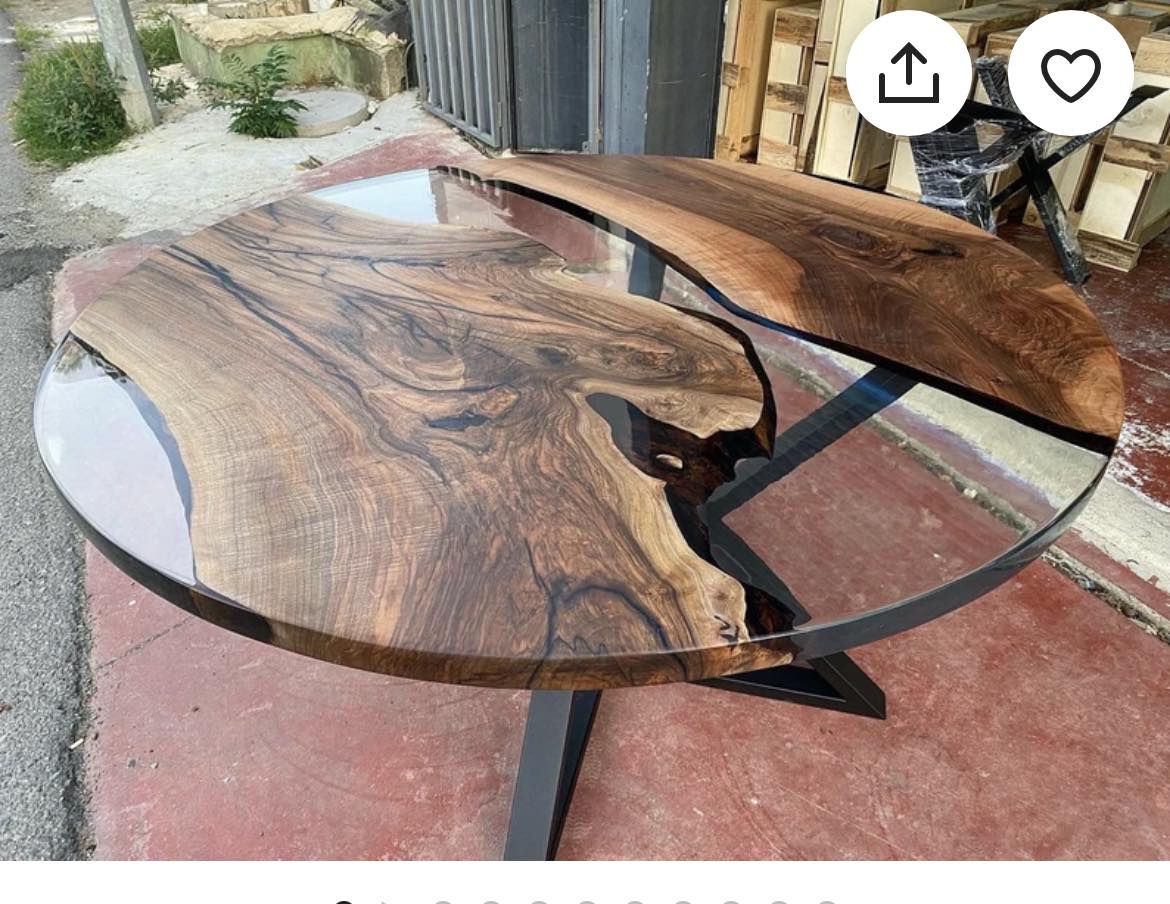

Slow Cure Casting Epoxy Resin (for thick pours)

Slow Cure Casting Epoxy Resin (for thick pours)

Couldn't load pickup availability

FULL SATISFACTION GUARANTEED!!

New Discounted Rates:

1G - $65

2G - $125 (save $5)

3G - $175 (save $20)

6G - $320 (save $70)

12G - $600 (save $180)

Slow Cure Casting Epoxy Resin:

This resin has longer curing time and therefore is suitable for project where thick pours are required such as River Tables etc. You can do up to 2" pour at a time and if you need more thickness, give a gap of at least 6 hours and do another pour on top of the previous one.

It comes in two parts - Resin & Hardener. These two parts MUST be mixed in precise ratio and mixed well to get best results.

Features:

Crystal clear, high gloss and transparent, yellow resistant

Automatic leveling and anti-foaming

Low set-to-touch and cure time

Goes well with pigments of all colors

Non toxic, low odor and low VOC

High hardness after drying

Glossy like mirror

Technical Specifications:

Ratio A to B: 2.7 to 1 (by volume) OR 3 to 1 (by weight)

Pot Life: 45 to 60 min

Coverage: 1" thickness of 1 sqft area requires about 2.5 L (Part A + B)

Set to touch time: 36 to 48 hrs

Curing Time: 72 to 96 hrs (varies based on ambient temp / humidity / thickness)

Surface ready to use time: 96 hrs

Directions:

Step 1: Wear safety glasses and gloves. Measure 2.7 parts of part A and 1 part of part B by volume (OR 3 to 1 by weight). Mix thoroughly.

Step 2: Make sure the surface area is horizontal to the ground and leveled. Pour the epoxy on the surface all the way through the area. This epoxy self levels itself so no need to move it around with any tools. Let the epoxy fall over the edges and coat the vertical edges. The liquid epoxy that falls over the edges will form bumps and there is no need to worry about that. These can be sanded off once the epoxy is dried and cured.

Step 3: If multiple flood coats are to be applied, make sure that each flood coat is less than 2" thick and maintain a gap of 4 hours between each flood coat.

Step 5: Pop air bubbles using a heat gun or plumber torch.

Step 6: Leave the surface for epoxy curing

MSDS can be downloaded from here

Materials

Materials

Dimensions

Dimensions

Care information

Care information

Slow cure epoxy

Have used it a lot have had great results with it

Deep pour

Excellent service and product Will be back to buy more once I’ve used the last order up

I’ve been using this for a few years and will continue using it.

Absolutely Amazing Resin

For all Resonators, it's absolutely amazing resin. Highly recommend to use! Clear, Small amount of the bubbles. Eazy to mix. Not changing colors ( yellow) during the time. Absolutely great customer service! I Love this company and this brand!

slow cure resin

We've used Trustic's slow cure resin on 8 or so projects. Great results every time. The Trustic staff has always been easy to work with. Overall, a very good customer experience.